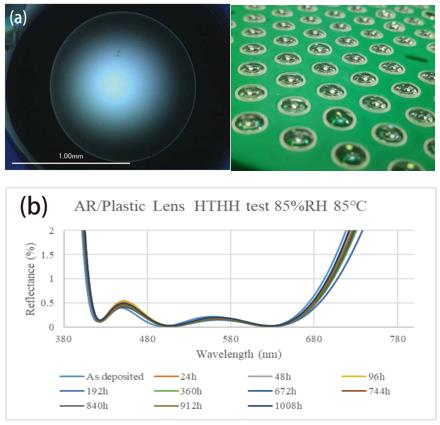

ALD coating technology is used for coating lenses such as mobile phone cameras to reduce ghostly glare caused by reflection. At the same time, the environmental testing effect of Optorun ALD coating is very good, and the reflection spectrum still remains unchanged after 1000 hours of aging test under 85 temperature and 85 humidity conditions.

ALD coating technology is used for coating lenses such as mobile phone cameras to reduce ghostly glare caused by reflection. At the same time, the environmental testing effect of Optorun ALD coating is very good, and the reflection spectrum still remains unchanged after 1000 hours of aging test under 85 temperature and 85 humidity conditions.

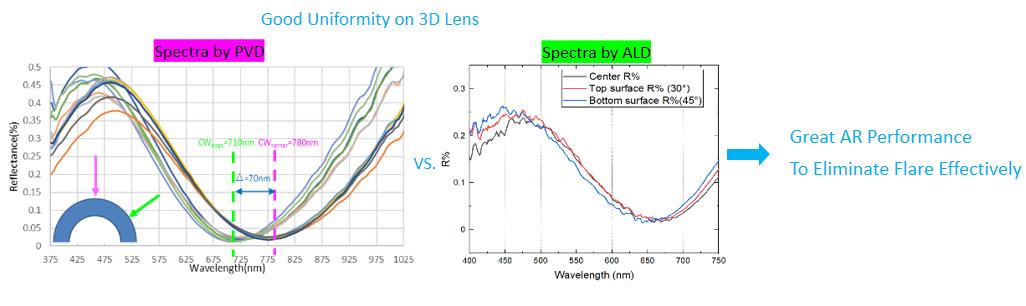

Compared with PVD coating technology, ALD coating technology can achieve the best coating uniformity and shape preservation on the surface of 3D substrates. This is difficult to achieve with PVD coating.

(a) No bubbles or cracking (b) Negligible wavelength shift after HTHH test

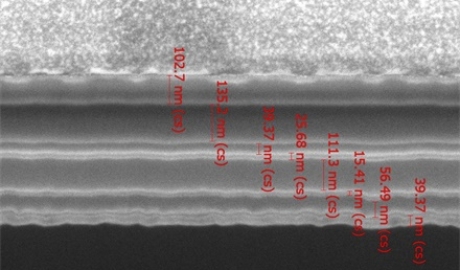

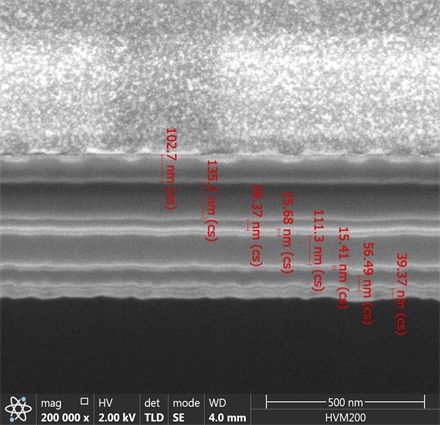

Good adhesion and conformality shown by the cross section of ALD SiO2/TiO2 coating on substrate, sampling by FIB and SEM

ALD coating technology is used for coating lenses such as mobile phone cameras to reduce ghostly glare caused by reflection. At the same time, the environmental testing effect of Guangchi ALD coating is very good, and the reflection spectrum still remains unchanged after 1000 hours of aging test under 85 temperature and 85 humidity conditions.

Follow official account

Copyright ? 2023 Optorun Semiconductor System Corporation 滬ICP備2023009503號-1